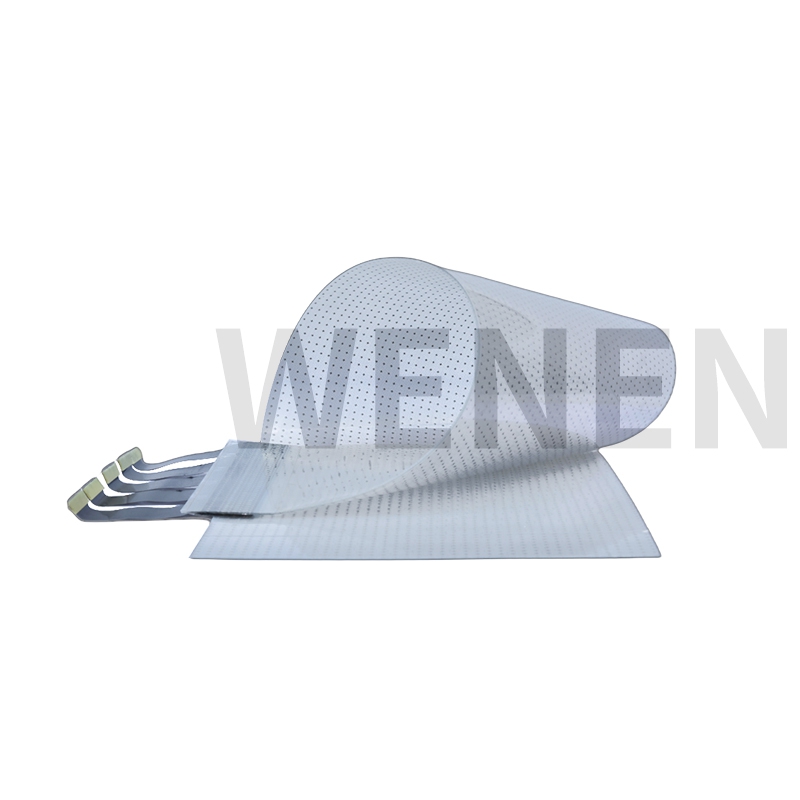

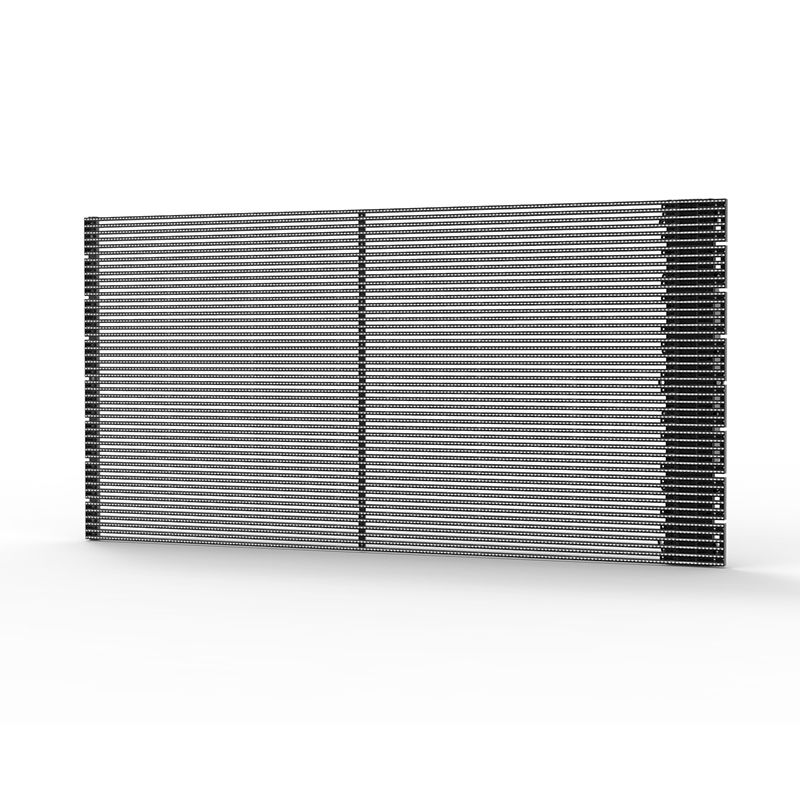

The significance of LED transparent film screen products with ultra-thin design lies in the fact that ancient buildings can also bear the screen body. Due to structural and lifespan issues, some buildings may not have sufficient external loads to accommodate traditional and overly heavy screens, but the lightweight design of ultra-thin screens can solve this problem; Some buildings lack sufficient indoor space, and lightweight LED screens can break this bottleneck.

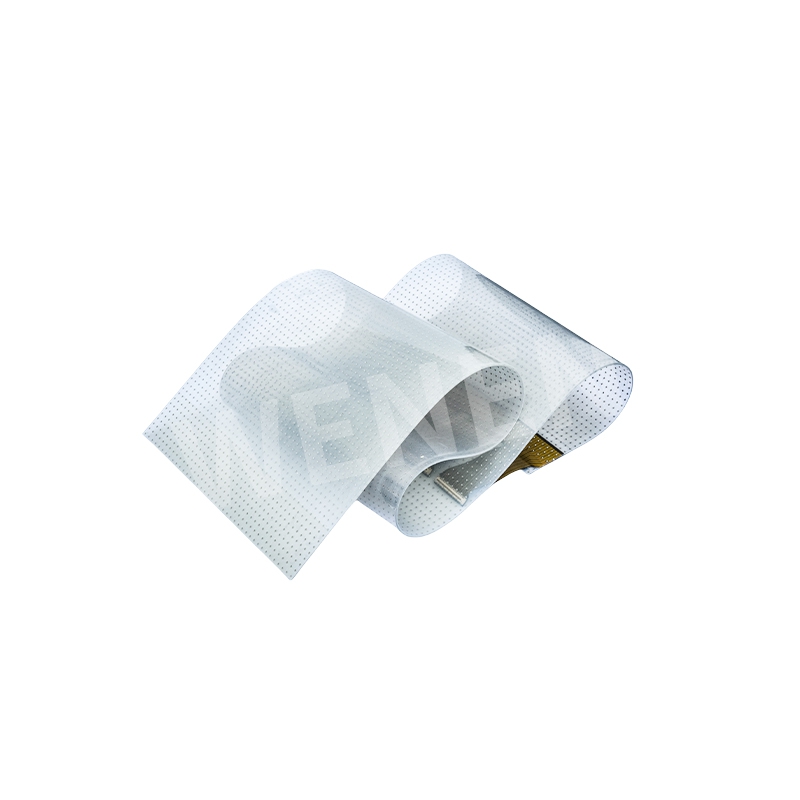

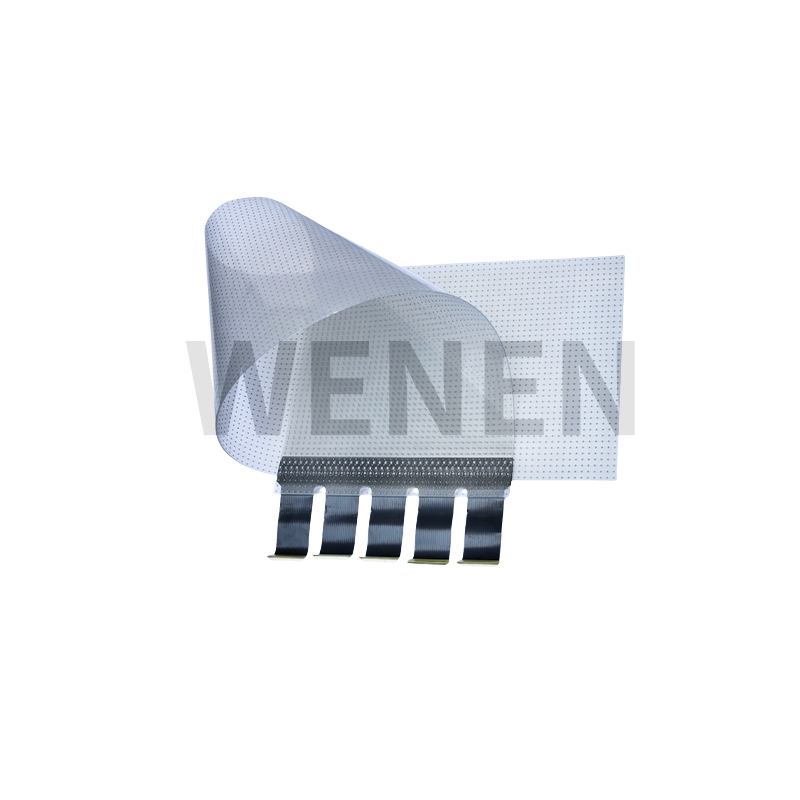

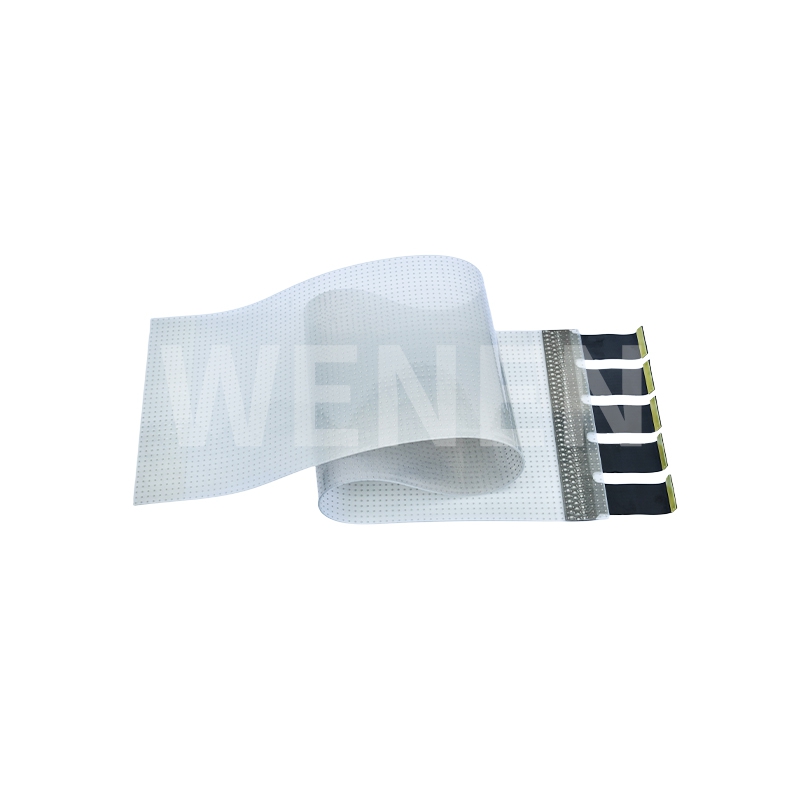

The benefits of a flexible LED transparent film screen design are that it can meet the perspective requirements of corner applications and create differentiated and irregular displays. Although these display requirements can also be achieved using conventional products, flexible products can achieve better levels of detail and a wider range of product applicability - that is, a standardized flexible unit can be assembled to create completely different shaped structures with different effects. Realize large-scale standardized manufacturing of irregular displays.

For the design of LED transparent film screens, ultra-thin is a prerequisite for flexibility. Only sufficiently thin units can achieve greater flexibility in curvature changes within the structural load-bearing range, and even fold directly. At the same time, ultra-thin and flexible designs mean the adoption of new material technologies, including PCB boards, casings, LED beads, etc., all require a completely new system.

1. In engineering applications, thermal design is the core

For outdoor display screens, the heat dissipation design should not only consider the internal heating problem, but also the external sunlight heating problem. Due to the high contrast design and low surface reflectivity of LED screens, most sunlight exposure is converted into heat and accumulated. For indoor display screens, there is no threat of sunlight. However, the smaller the spacing between screens, the higher the density of the lamp beads, that is, the higher the density of the heat source, and the higher the requirements for the thinness of the product, and the limited heat dissipation and convection space around the product. These factors make the heat dissipation design of small pitch LED transparent film screens not simple.

There are three main aspects to thermal design: the first is to reduce heat sources. This adopts more efficient lamp bead products, more efficient unit power supply and driving equipment. Secondly, enhance heat resistance. Including thermal aging and stability design, material selection, etc. for lamp beads, electronic components, and bonding components. The third aspect is the design of active and passive heat dissipation structures. From the perspective of passive heat dissipation, including the heat dissipation efficiency of the front side of the screen, air convection resistance, etc; The thermal conductivity structure on the back of the screen bead layer, etc. The active heat dissipation design mainly involves active air convection and noise control within the LED transparent film screen.

The degree of thermal stability is related to the practical application indicators such as the lifespan, defect rate, and operation and maintenance cost of LED transparent film screens, while also limiting their applicable environment. More importantly, the lightweight LED transparent film screen must be built on a highly redundant thermal design. Lightweight products have the characteristics of small internal space, insufficient air convection, and more serious internal heat accumulation problems; Flexible units may face more severe material thermal aging and more complex internal convection structures.

2. Innovation exchange in industries

Whether it‘s ultra-thin, flexible, or thermal design, LED transparent film screen products are inseparable from the technological progress of LED beads. As a leading domestic LED transparent film screen enterprise, Weineng Semiconductor would like to share its views on this matter. At present, the opposition in the domestic LED screen industry is very strong, and the competition and hostility between enterprises are clear. There is a lack of common topic discussions among enterprises. There are three reasons for the formation of this situation:

From a historical perspective, the domestic LED screen industry has been a typical industry that follows the pace of foreign products and achieves entrepreneurial development by replacing imports. In this development process, there is no need for strategic decision-making, and following the strategy is sufficient to complete the direction selection. At the same time, this development process is prone to price based competition, leading to hostility and distrust among enterprises.

From the perspective of industrial spatial structure, the scale of the domestic LED screen market has regional and industrial characteristics. Considering the large scale and rapid growth of the overall domestic market, it is easy for many enterprises to survive and develop independently, and can also achieve good results. This is the unique feature of a latecomer explosive market.

From the perspective of technological status, homogenization is a relatively serious problem. Therefore, the foundation for communication between manufacturers is not strong. In the product market, the dominance of "project driving force" is becoming increasingly clear. Especially for large enterprises, they often dominate the high-end market and are particularly influenced by project driving forces. This has increased the competitive barriers within the industry.

Whether it is ultra-thin, flexible, or thermal structure design, it cannot be separated from the innovation of LED beads. Flexible screens require small and bright LED design; Ultra thin products require the lightness and thinness of the lamp beads themselves; Thermal design requires the lamp beads to have higher light efficiency, better thermal balance structure, better heat resistance, and reliable working indicators in different thermal environments. In fact, not only LED bead products, including emerging PCB materials, electronic copper materials and technologies, LED process equipment, etc., all require a unified development direction and strategic expression for the LED transparent film screen industry, and require communication and interaction between upstream and downstream industries. From this perspective, the LED transparent film screen industry not only requires product innovation, but also the innovation of the entire industry‘s "industrial structure".