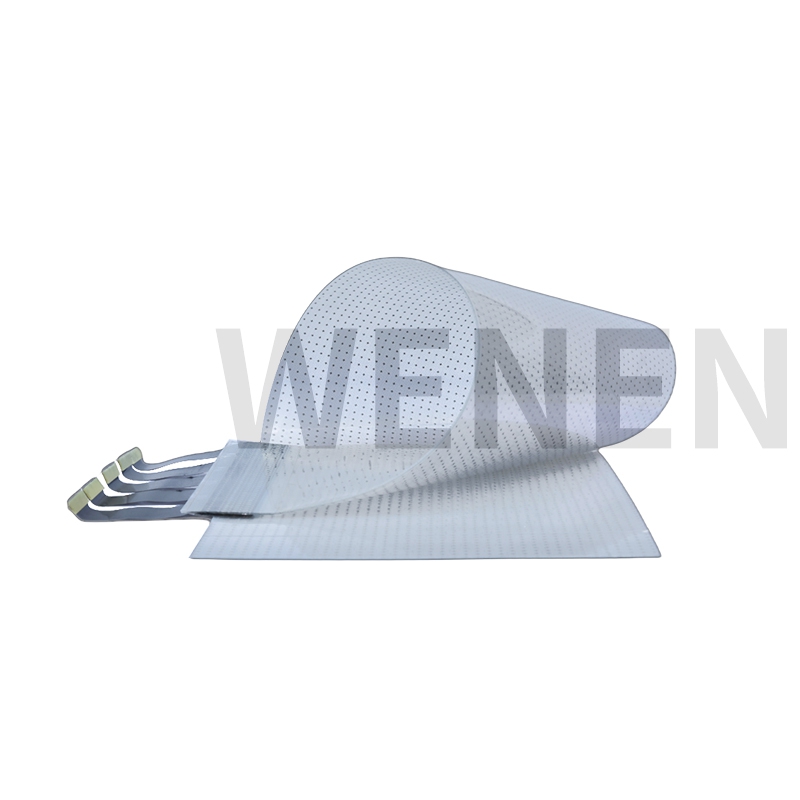

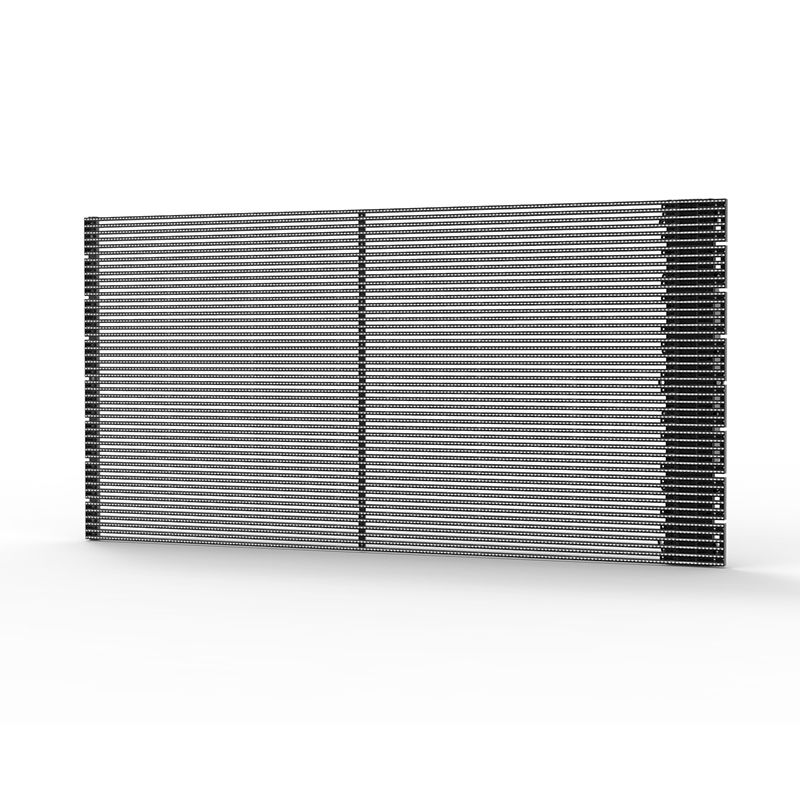

Ultra-thin design LED transparent film screen products, the greater significance is: old buildings, can also carry the screen. Some buildings due to structural and longevity issues, the external load is not enough to meet the traditional, too heavy screen, but the lightweight of the ultra-thin screen can solve this problem; some other buildings have insufficient space for indoor use, the thin and light LED screen can break this bottleneck.

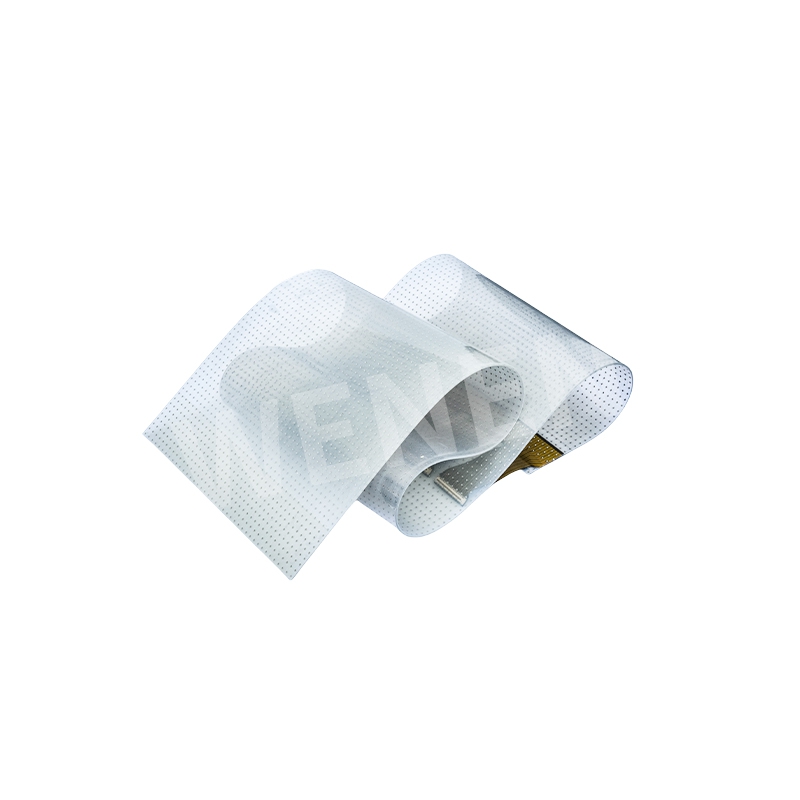

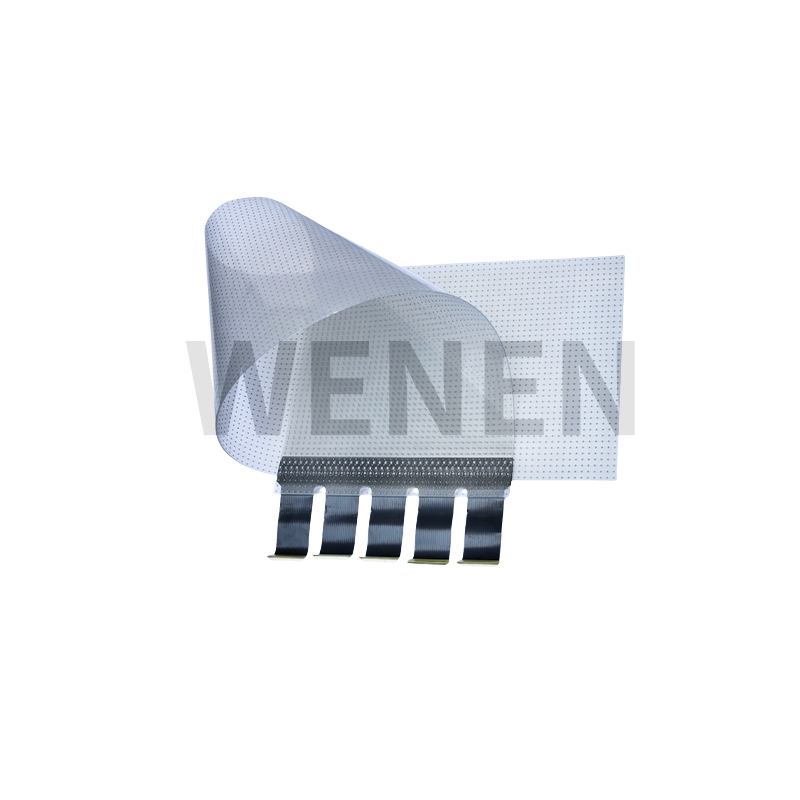

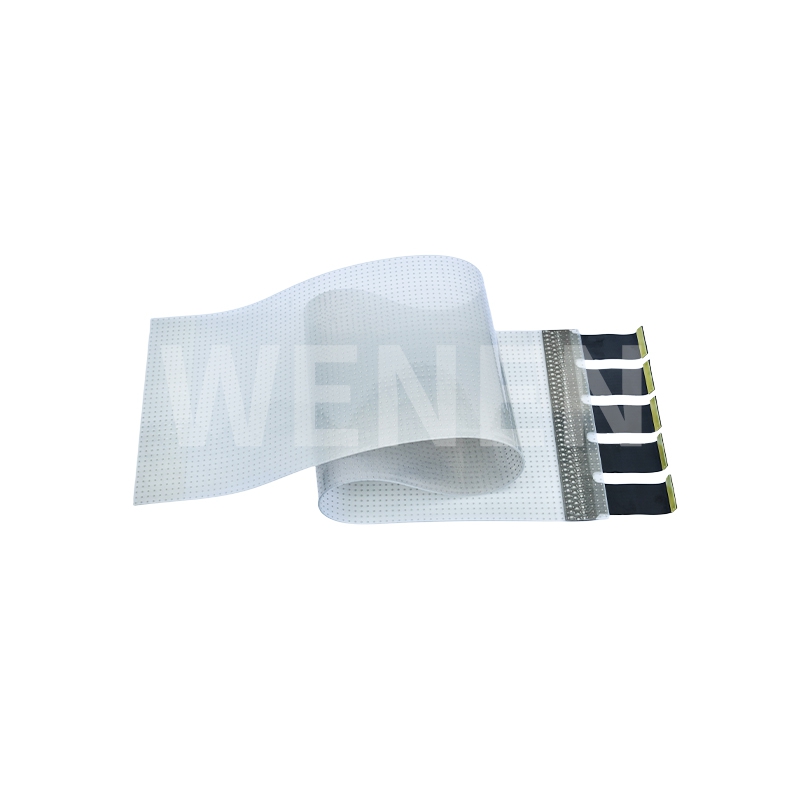

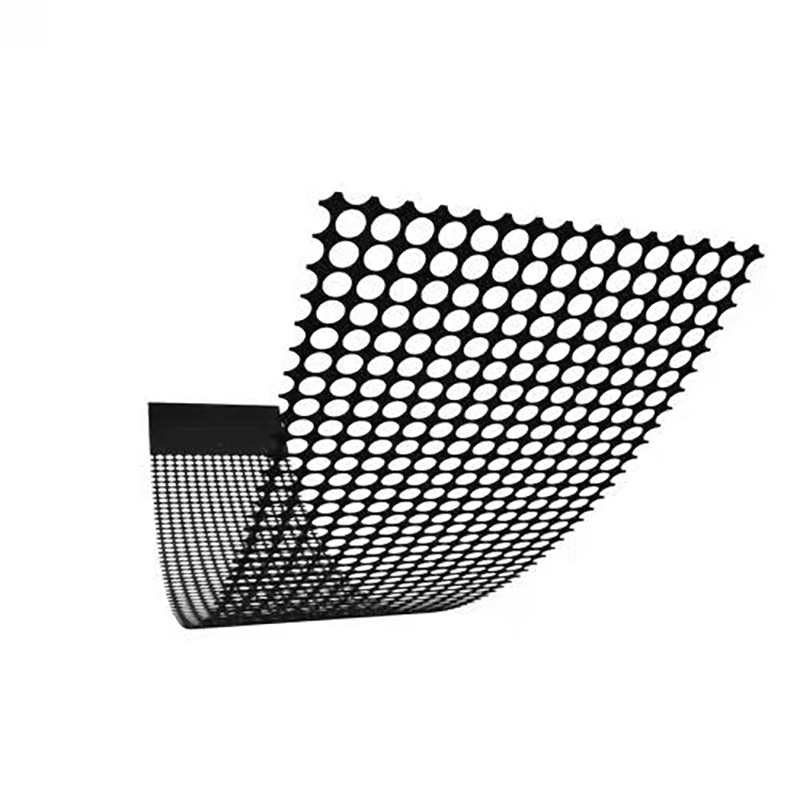

The benefits of flexible LED transparent film screen design, can meet the corner of the application of the viewing angle requirements, while helping to create a differentiated shaped display. Although these display needs, the use of conventional products can also be achieved, but flexible products can achieve a better degree of detail and a wider range of products applicable space - that is, a standardized flexible unit, can be spliced to create a completely different effect of the shaped structure. Achieve large-scale standardized manufacturing of shaped display.

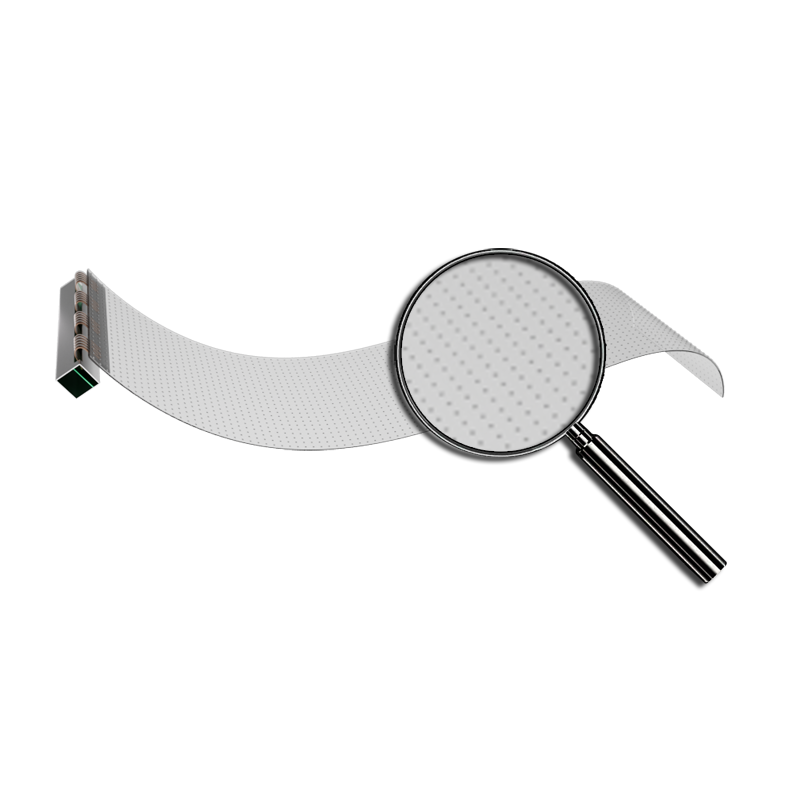

For LED transparent film screen design, ultra-thin is the premise of flexibility. Only thin enough unit, in order to achieve greater flexibility in the structure within the range of bearing force, the arc changes, and even direct folding. At the same time, both ultra-thin and flexible design means the use of new material technology: including PCB boards, housings, lamp beads, etc. require a completely new system.

1.Engineering application, thermal design is the core

For outdoor display screens, thermal design should not only consider the internal heat generation problem, but also need to consider the heating problem of external sunlight. As the LED screen more high contrast design, surface reflectivity is very low, so most of the sunlight will be converted into heat accumulation. For indoor display screens, there is no threat of sunlight. However, the smaller the pitch of the screen, the higher the density of lamp beads, that is, the higher density of heat sources, and the product is more lightweight and thinness requirements, the product around the heat dissipation convection space is limited. These factors make the small pitch LED transparent film screen thermal design is not simple.

There are three main aspects of thermal design: the first is to reduce the heat source. This uses more efficient lamp bead products, more efficient unit power supply and drive equipment. The second is to enhance heat resistance. Including lamp beads, electronic components and glued parts of the thermal aging and thermal stability design, material selection and so on. The third aspect is the design of active and passive heat dissipation structure. From the passive heat dissipation point of view, including the front side of the screen thermal efficiency, air convection resistance, etc.; screen bead layer back of the thermal conductivity structure. Active heat dissipation design is mainly active air convection and noise control within the LED transparent film screen.

The degree of thermal stability, the relationship between the LED transparent thin film screen life, defect rate, operation and maintenance costs and other practical application indicators, but also to limit its application environment. More importantly, thin and light LED transparent film screen, must be built on a highly redundant thermal design. Thin and light products with small inner space, air convection is insufficient, the internal heat accumulation problem is more serious; Flexible unit may face the material thermal aging is more serious, the internal convection structure is more complex problems.

2. Industry‘s innovation exchange

Whether it is ultra-thin, flexible or thermal design, LED transparent film screen products are not around the technological advances in LED lamp beads. Weineng Semiconductor, as a leading domestic LED transparent thin film screen enterprises, to talk about their own views on this. At present, the domestic LED screen industry is very strong antagonism, the competition between enterprises hostile clear, common topics between enterprises to explore the relatively lack of. There are three reasons for the formation of this situation:

From the historical point of view, the domestic LED screen industry is to follow the pace of foreign products to replace imports to achieve entrepreneurial development of the typical industry. This development process, do not need strategic decision-making, follow the strategy is enough to complete the direction of choice. At the same time, this development process is easy to fall into price-based competition, which in turn leads to hostility and distrust between enterprises.

From the perspective of industrial spatial structure, the domestic LED screen market size has the color of regionalization and industrialization. Combined with the overall domestic market size, growth is relatively rapid, it is easy to form a lot of enterprises “self-care” survival and development, can also achieve very good results phenomenon. This is the unique characteristics of the late burst of large markets.

From the current state of technology, homogenization is a relatively serious problem. As a result there is little basis for communication between vendors. In the product market, the dominance of the “project driver” is becoming clearer and clearer. Especially large companies, often dominate the high-end market, especially by the “project-driven” influence. This increases the competitive divide in the industry.

Whether it is ultra-thin or flexible, or thermal structure design can not be separated from the lamp bead innovation. Flexible screen requires small and bright lamp bead design; ultra-thin products require lamp beads themselves thin and light; thermal design requires lamp beads themselves have a higher light efficiency, better thermal balance structure, better heat resistance and different thermal environment under the reliable working index. In fact, not only lamp bead products, including emerging PCB materials, electronic copper materials and technology, LED process equipment, etc., all need LED transparent film screen industry has a unified development direction and strategic expression, need to upstream and downstream industry communication and interaction. From this point of view, the LED transparent film screen industry not only needs product innovation, also need the whole industry “industrial structure” innovation.