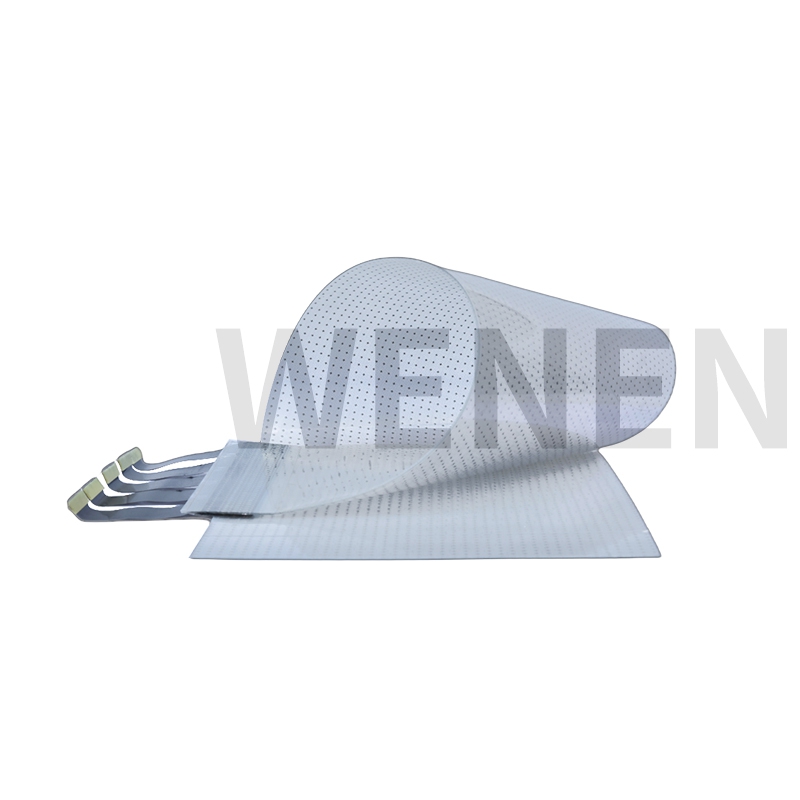

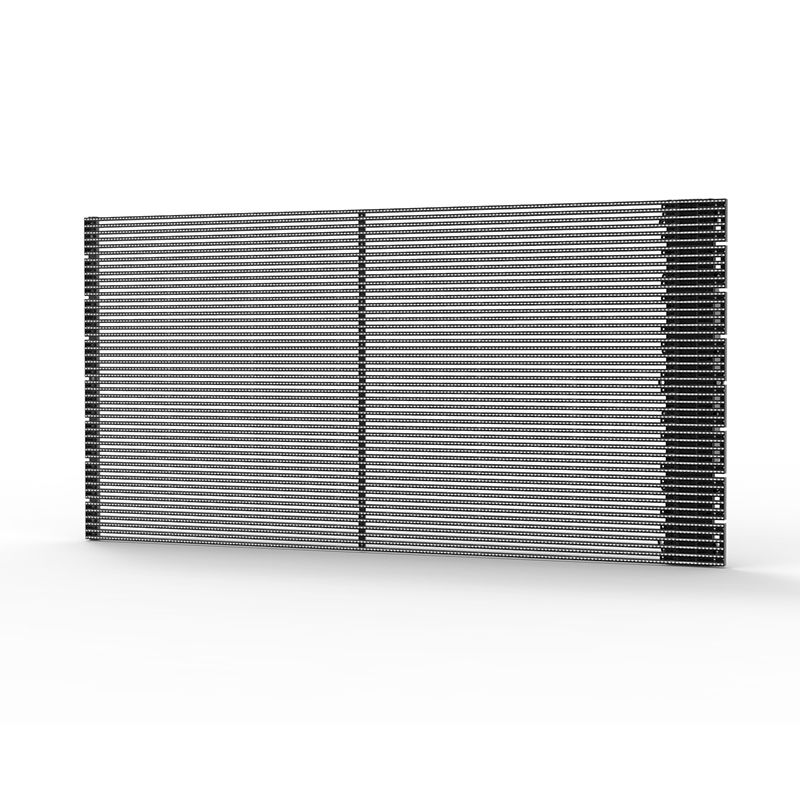

Traditional LED transparent screen resolution has been greatly improved, small pitch LED transparent screen is based on this new product, small pitch transparent screen refers to the LED point spacing in P2.5 and the following transparent screen products. At present, the small pitch LED display there are still 3 contradictions to be reconciled, such as can not be properly resolved will very much affect the use of LED transparent screen experience:

1, brightness reduction brought about by the loss of gray scale

The most significant difference between indoor and outdoor display applications is the change of ambient light. When the LED transparent screen comes indoors, its brightness will need, but when the transparent screen brightness reduced to 600cd / ㎡ below, the picture began to appear more obvious gray loss phenomenon, with the further reduction of brightness, gray loss is also more and more serious. We know that the higher the grayscale level, the more colorful the transparent screen screen display, the picture is more delicate and full.

Solution: The brightness of the screen body applies to the environmental brightness, which can be automatically adjusted. Avoid the impact of the environment is too bright or too dark, to ensure that the picture quality is normal. At the same time, the use of high gray level of the screen body, the current Venable Semiconductor self-developed with the paste - crystal film screen gray level can reach 16bit.

2, picture quality improvement brought about by the increase in bad points

Small pitch LED transparent screen consists of many LED lamp beads, and the distribution is dense. The greater the number of LED lamp beads per unit area, the more high-definition flexible transparent screen picture quality, the richer the display of picture details. However, due to technical defects, small pitch transparent screen is prone to lamp bead bad point, general LED display dead rate standard is controlled within three ten thousandths, but for small pitch LED transparent screen, three ten thousandths of the dead rate can not meet the daily use of the required, take the P4 small pitch LED transparent screen, there are 62,000 lamp beads per square meter. Assuming a screen area of 4 square meters, the number of dead lights will be 6.2 * 3 * 4 = 75, will bring unfriendly viewing experience to the normal screen display.

Solution: dead lamps are generally beads welding is not solid reason, on the one hand, LED transparent screen manufacturers production technology process is not pass, there is a problem with quality control. Of course, do not rule out the problem of lamp beads. So manufacturers must be in accordance with the formal quality inspection process to control the quality of raw materials, while the production process monitoring in place. Before leaving the factory, must also do 72 hours aging test, overhaul and check the dead light problem, to ensure that before shipment is qualified products.

3, the problem of heat brought about by close viewing

Studies have shown that in the LED screen energy conversion process, electro-optical conversion efficiency of about only 20 ~ 30% or so, that is to say, only about 20 ~ 30% of the input electrical energy is converted to light energy, and the remaining 70 ~ 80% of the energy are all consumed in the form of heat radiation, therefore, the LED display screen heating is serious. Long-term heat small pitch LED transparent screen, heat dissipation will lead to increased indoor environmental temperature, for indoor personnel, stay for a long time, it will be relatively uncomfortable, and even if it is sitting relatively far away from the location, it is difficult to maintain a good state of mind under the heat for a long time.

Solution: The use of high-quality high-efficiency power supply can ensure a high electro-optical conversion rate, thereby reducing the impact of heat.